Profilometer Measurements, Analysis and Reporting (Rutting and IRI)

Profilometer Measurement Equipment measurements are carried out by KOMSA at home and abroad to determine the functional status of Highway Pavements and Airport Pavements.

Features:

* Measurements are made in accordance with ASTM E950 – Class 1 Standard.

* All data is collected, analysed and stored in Real Time.

* With the “Stop and Go” feature, data can be collected in the 0-120 km/h speed range.

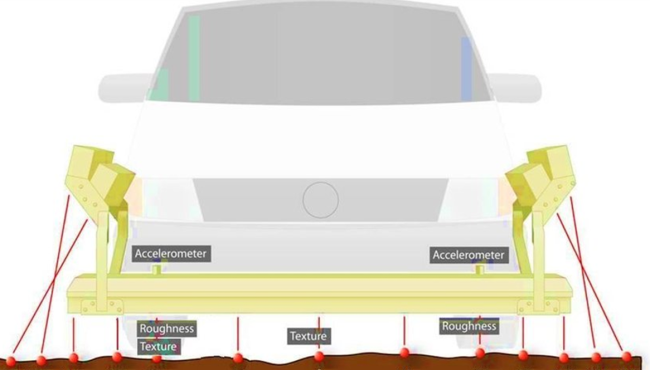

Profilometer Measurement Equipment collects the profile of the pavement with a laser and accelerometer system and performs IRI (International Roughness Index), Rutting and Surface Deterioration Image measurements. The profilometer measurement device also collects additional data such as Global Position (GPS) and Measurement Speed.

KOMSA measurement and analysis team used the Dynatest brand Profilometer measuring device on approximately 10,000 km of roads throughout Turkey, in accordance with the ASTM E-950 standard A Class 1 and the criteria in the World Bank Technical Declaration No. 46 (standards accepted by the General Directorate of Highways), made the measurements and completed the analysis and evaluation of obtained data for;

Roughness (IRI),

Rutting,

Macro Texture,

Inertial Motion Data (Geometric Measurements),

Road Surface Deterioration Images

Profilometer Measurement Equipment

Profilometer Measurement Made by Komsa on Fatih Sultan Mehmet Bridge

For all these sections measured with a profilometer;

The current situation has been determined,

Appropriate maintenance and repair alternatives were determined according to future traffic projections and

Benefit/Cost analysis was performed on these alternatives and the most appropriate solution was determined.

In addition, at the network level;

Future structural and functional status predictions,

Maintenance – repair priority analysis and

Budget arrangements are also among the works carried out.

The measurements made are analysed using software prepared by KOMSA in accordance with World Standards and Highways legislation. All analysed data are examined and evaluated by KOMSA analysis engineers and reports are prepared in accordance with the Highways Specifications. The analysis programs used in the General Directorate of Highways were made by KOMSA specifically for KGM

Roughness (IRI) Values

KOMSA IRI analyses are carried out by KOMSA experienced engineers in accordance with the General Directorate of Highways, ASTM and AASHTO regulations. During the evaluation phase, the photographs recorded by the Profilometer Measuring Device Road Camera at 20 m intervals during measurement are examined and compared with the Irregularity (IRI) values. The sections whose evaluations are not suitable are examined one by one, and the sections that give negative results due to external factors, although there is no problem on the coating surface, are evaluated by stating the reasons in the report.

Roughness Measurements (IRI) with Profilometer

Evaluation results are reported in detail in line with the criteria determined by the General Directorate of Highways and are prepared with due diligence in accordance with the format of the General Directorate of Highways.

All Roughness (IRI) analyses and evaluations made by KOMSA can be viewed and printed at any time by KOMSA web-based software. All measurements and analyses made can be examined by transferring them to the map in Geographic Information Systems with KOMSA software.

Rutting Values

With the profilometer measurements made by KOMSA, the amount of rut settlement is determined separately for the right and left ruts of the road. These collected data are evaluated by KOMSA experienced engineers. During the evaluation phase, the photographs recorded by the Profilometer Measuring Device Road Camera at 20 m intervals during measurement are examined and compared with the Sitting in Wheel Tracks (TIO) values. The sections whose evaluations are not suitable are examined one by one, and the sections that give negative results due to external factors, although there is no problem on the coating surface, are evaluated by stating the reasons in the report

Profilometre İle Tekerlek İzinde Oturma (TİO) Ölçümü

Evaluation results are reported in detail in line with the criteria determined by the General Directorate of Highways and are prepared with due diligence in accordance with the format of the General Directorate of Highways.

All Rutting analysis and evaluations made by KOMSA can be viewed and printed at any time by KOMSA web-based software. All measurements and analysis made can be examined by transferring them to the map in Geographic Information Systems with KOMSA software.

KOMSA Roughness (IRI) and Rutting Evaluation Screenshot